- Enamel insulated wire

- Small precision small enameled flat wire

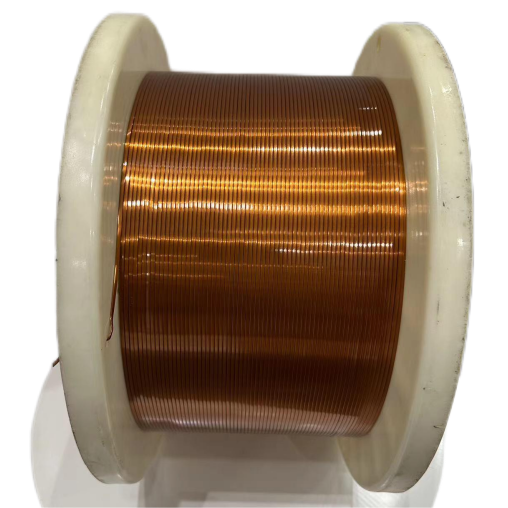

- Enamelled copper flat wire stand

- Enameled rectangular wire

- Enameled round wire

- 240 grade aromatic polyimide enameled

- Paper winding wire series

- Cable cable

- NOMEX paper envelope

- Non-woven polyester film wrapping wire

- Polyimide film wrapping wire

- reinforced mica tape wrapped copper flat wire

- reinforced mica tape wrapped copper flat wire

- Polyimide film sintering line series

- Polyimide film sintering line

- Glass fiber package polyimide film sintering line

- Mica tape wrapped polyimide film sintered wire

- Glass package winding wire series

- Glass envelope

- Glass wire enameled wire

- Glass film wrapped around the wire

- glass wrap mica tape around the envelope

- Electrician wire series

- Electrician aluminum flat wire

- Electrician copper flat wire

240 Grade Aromatic Polyimide Enameled Copper Flat Wire

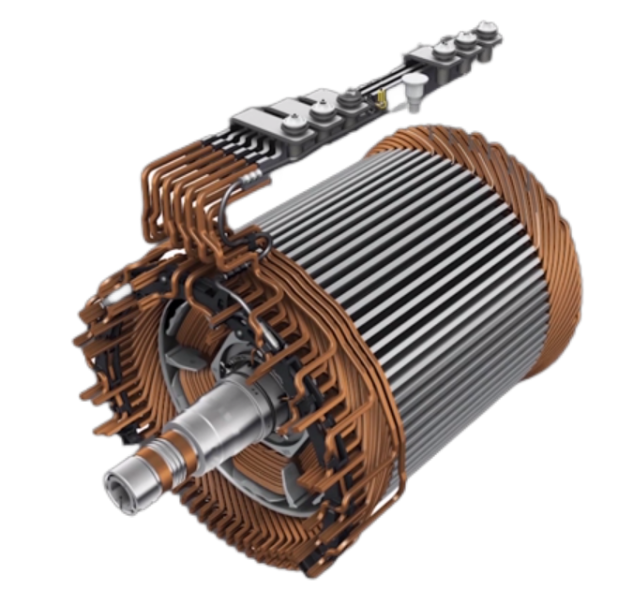

240 grade aromatic polyimide enameled copper flat wire is electrician round copper rod extruded or drawn by certain specifications of the mold annealing treatment of the wire, the use of mold-type paint coated with a multi-channel polyimide insulating varnish, baking treatment, so that the insulating varnish and the wire to form a whole. The product has high temperature resistance and high flexibility, and can be applied to new energy vehicles, military aerospace, rail transportation, nuclear power and other fields, with a heat-resistant grade of 240℃.

Product Categories

▲240 Polyimide Enameled Copper Flat Wire

Standards:GB/T7095.5-2008 ;

Raw Material

Conductor: T1 purple copper/TU2 purple copper

The resistivity of copper flat wire can not be more than 0.017241Ωmm2 / m in 20 ℃

Varnish: Polyimide.

Production range

Narrow side size a:0.4mm—4.00mm

Wide side size b:2.50mm—15.00mm

The recommended ratio of width and thickness: 1.5<b/a<20

Product Enamelled Thickness:

60μm≤Thickness of paint film on both sides≤120μm

If the use of specifications beyond the above range, please contact us

Features and advantages

Product Features

► High conductivity, low impedance

► Superior high temperature resistance.

► Excellent softening breakdown resistance and heat shock resistance.

► Excellent dielectric properties and stable chemical properties.

Product Advantages

Advantage 1: High thermal stability

Polyimide enamelled wire has high thermal stability and is able to maintain its physical and chemical properties at high temperatures. The glass transition temperature and decomposition temperature are relatively high, and no harmful volatiles are produced at high temperatures.

Advantage 2: Good chemical stability

Polyimide enamelled wire has good corrosion resistance to most chemicals, and has better chemical resistance than polyamide imide (PAI) and polyester imide (PEI).

Advantage 3: Good electrical insulation

Polyimide enamelled wire is an excellent electrical insulation material with high resistivity and dielectric constant, so it has been widely used in the fields of electronics, electricity and communication.

Advantage four: high mechanical strength

Polyimide enamelled wire has high tensile strength, bending strength and impact toughness, and good wear resistance.

Advantage five: Good radiation resistance

Polyimide enamelled wire has good resistance to radiation, so it has been used in military, medical, aerospace, nuclear industry and other fields.